Navigating Supply Chain Complexity: Strategies for Effective Management in a Globalized Market

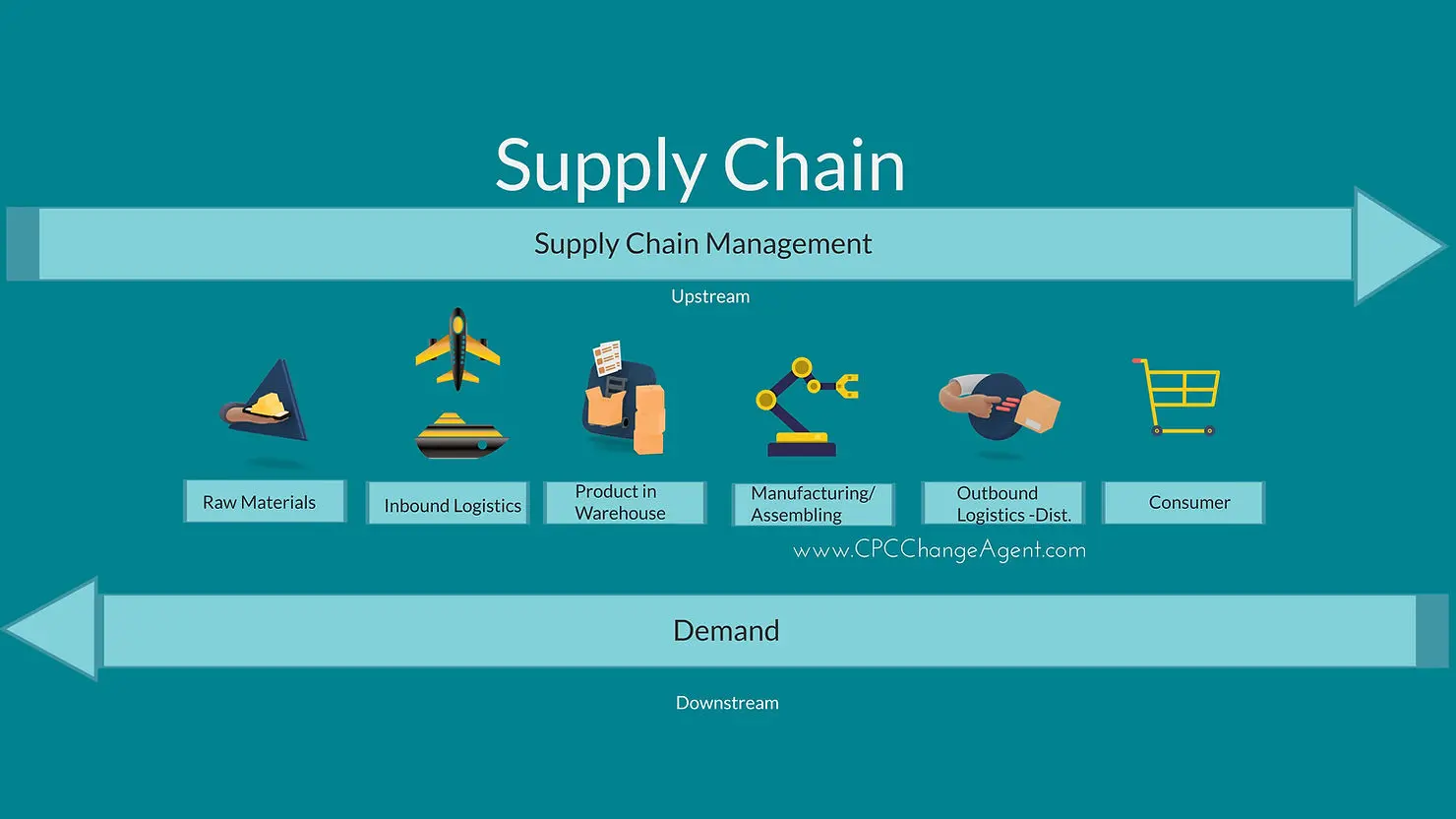

Supply chain refers to the steps needed to get a service or product to the customer and involves people, vendors, systems, processes, and suppliers, associated with from designing to delivering a product to the customer. The larger the organization, the more mind-boggling a supply chain becomes. In contrast, the more localized or confined the business, the less complicated the supply chain. Consequently, the steadily developing intricacy of getting products to an ever-growing pool of potential customers over various platforms involves state-of-the-art supply chain management to keep up with agile, robust systems, recognize current bottlenecks, and anticipate future ones.

Supply chain management has become a critical aspect of business operations in today’s globalized and highly competitive market. It involves managing the flow of goods and services from the point of origin to the point of consumption, ensuring efficiency, cost-effectiveness, and timely delivery.

One key factor that has contributed to the increasing complexity of supply chains is globalization. As companies expand their operations globally, they must deal with multiple vendors, suppliers, and partners across different geographies. This not only adds layers of complexity but also increases the risk of disruptions in the supply chain.

Moreover, with customer demands becoming more diverse and dynamic, supply chain management has to be flexible and adaptive to keep up with changing market trends. This requires constant monitoring, evaluation, and optimization of supply chain processes to ensure that customer demands are met efficiently and effectively.

Another critical aspect of supply chain management is risk management. With the increasing frequency of natural disasters, economic crises, and other disruptive events, supply chains are vulnerable to various risks that can have a significant impact on operations. As such, companies need to implement comprehensive risk management strategies to mitigate potential disruptions and maintain business continuity.

In conclusion, supply chain management is a vital aspect of modern business operations that requires constant optimization and adaptation. With the ever-growing complexity of global markets and changing customer demands, companies must invest in robust supply chain systems and strategies to remain competitive and ensure customer satisfaction. Effective supply chain management can ultimately lead to increased efficiency, reduced costs, and improved customer relationships, making it an essential component of sustainable business success.

One of the key goals of supply chain management is to ensure sustainability and minimize the environmental impact of operations. With growing concerns about climate change and resource depletion, companies are under pressure to adopt sustainable practices in their supply chains. This includes implementing environmentally friendly processes, reducing waste, and sourcing materials from ethical suppliers.

Supply chain

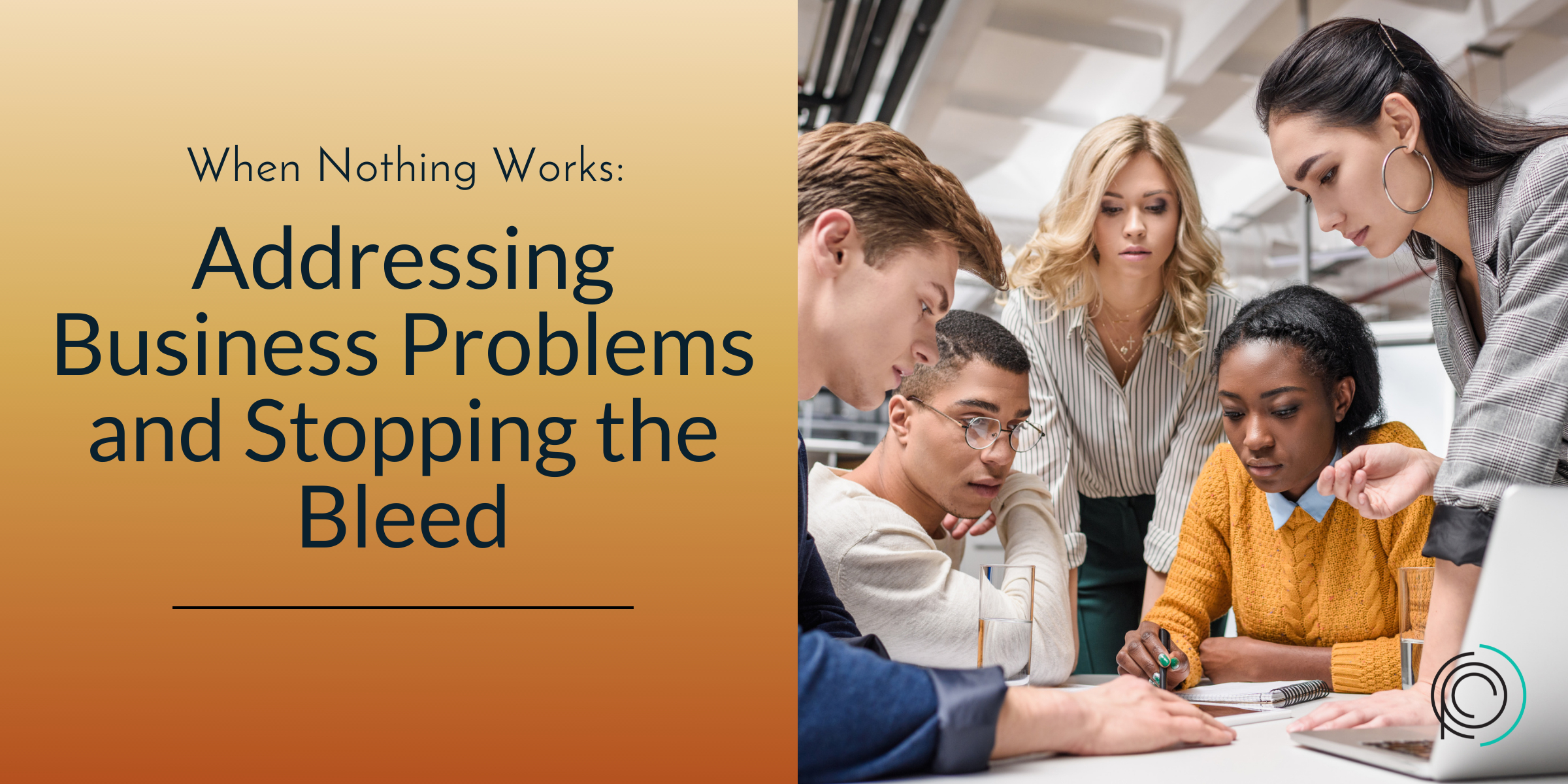

Notwithstanding, supply chain management can be traumatic for supply chain managers in times like these, especially in and after the wake of COVID-19. The market has become even more volatile due to the pandemic increasing the already stressed space. On the other hand, a day’s delay in arriving goods can lead to the loss of many days of work in a supply chain since the great resignation has created an environment with less talent.

To tackle these challenges, supply chain management must also focus on building resilience and agility within the supply chain. This involves having alternative suppliers and backup plans in place to mitigate disruptions and quickly adapt to changing market conditions. Additionally, investing in technology such as artificial intelligence, data analytics, and automation can help optimize supply chain processes and make them more efficient.

While managing a supply chain can be complicated, it is crucial for businesses to stay competitive and meet the demands of modern consumers. By focusing on sustainability, risk management, and resilience, companies can ensure a robust and efficient supply chain that drives business success. As technology continues to advance and markets become more unpredictable, effective supply chain management will only become more critical in achieving sustainable growth in the long run. So, it is essential for companies to continuously invest in and improve their supply chain management strategies to stay ahead of the curve in an ever-changing business landscape. Lastly, by prioritizing a customer-centric approach and maintaining adaptability and flexibility, businesses can achieve success in their supply chain operations amidst any challenges that come their way. So, never underestimate the importance of supply chain management and its role in achieving sustainable business growth. Let’s continue to innovate, optimize, and adapt our supply chains for a more efficient and resilient future. This concludes the content on supply chain management in Markdown format. Thank you for reading!

Identifying the Bottlenecks in a Supply Chain

Let us look at how to identify the bottlenecks of the supply chain. Fundamentally, identification is the most significant step to positive change. When a business chooses not to respond to problems it makes for a stagnant production and slower turnaround time. The thing to keep in mind is that bottlenecks include external factors affecting the process like raw materials, manufacturing, and shipment. Your supply chain is end-to-end, from ordering raw materials to delivery to your customer, so any bottleneck in the supply chain will have a domino effect down the line.

To identify bottlenecks in your supply chain, it is essential to analyze the flow of materials and information throughout the process. This can be done by mapping out the entire supply chain and identifying key touchpoints where delays or disruptions may occur. It is also important to gather data and insights from all stakeholders involved in the supply chain, including suppliers, manufacturers, logistics providers, and customers. This can help identify any inefficiencies or issues that may be causing bottlenecks.

Another crucial aspect of identifying bottlenecks is to monitor and track key performance indicators (KPIs) such as lead times, inventory levels, and on-time delivery rates. By closely monitoring these metrics, businesses can quickly identify any areas of the supply chain that are underperforming and address them promptly.

Additionally, conducting regular risk assessments can help identify potential bottlenecks before they even occur. This involves analyzing potential risks and developing contingency plans to mitigate their impact.

Detecting bottlenecks within the supply chain is vital for upholding a seamless and effective operation. Through diligent monitoring of performance metrics and proactive resolution of any inefficiencies or disruptions, companies can enhance their supply chain management and foster sustainable growth. Therefore, it is crucial to routinely evaluate and analyze your supply chain to pinpoint bottlenecks and introduce essential modifications to sustain ongoing success.

Another reason for bottlenecks in supply chain management can be the lack of planning of the process. The best way of identifying the bottlenecks is by analyzing the previously collected data and information, through process mapping your current state. The process can be slowed if your front-line team has not been given enough instructions, tools or the right resources to effectively and efficiently do their jobs.

Communication is change orders or project revisions is also a contributing factor to supply chain bottlenecks and overall business inefficiencies. In this case, implementing clear and effective communication channels, along with providing necessary training and resources to employees, can help mitigate bottlenecks in the supply chain.

Overall, a thorough evaluation of processes, identifying key touchpoints and potential risks, along with proper planning and effective communication, are crucial elements in detecting and addressing bottlenecks in a supply chain. By continuously monitoring and improving these aspects, businesses can ensure a smooth and efficient supply chain that drives success in the long term. Let us continue to prioritize supply chain management and work towards creating more resilient, agile, and sustainable supply chains for a better future. Thank you for reading! So, never underestimate the importance of supply chain management and its role in achieving sustainable business growth.

The lack of visibility remains another bottleneck with monstrous outcomes. According to a survey conducted by SupplyChain Digital, 78% of C-level executives need real-time visibility across their inventory network and supply chain. However, they still plan to put resources into intelligence, agility, and automation initiatives.

Lack of visibility can lead to inaccurate demand forecasting, resulting in overstocking or understocking of inventory. This not only affects a company’s bottom line but also leads to customer dissatisfaction due to delayed or cancelled orders.

To overcome this bottleneck, companies should invest in supply chain management software that offers real-time visibility and analytics. By having access to accurate and real-time data, businesses can make informed decisions and optimize their supply chain more effectively. Additionally, implementing technologies such as RFID, IoT sensors, and blockchain can further enhance visibility and transparency throughout the supply chain.

Identifying bottlenecks in a supply chain is crucial for maintaining efficient operations and achieving sustainable growth. By thoroughly evaluating processes, monitoring performance metrics, proactively addressing risks, and investing in technology, businesses can overcome bottlenecks and keep their supply chains running smoothly.

The Role of Technology in Supply Chain Management

Technology has played a significant role in transforming supply chain management in recent years. With the rise of e-commerce and globalization, businesses have had to adapt and evolve their supply chains to keep up with changing customer demands and market dynamics.

One of the main ways technology has impacted supply chain management is through improved visibility. As mentioned earlier, lack of visibility can create bottlenecks in the supply chain, leading to inefficiencies and increased costs. However, with the use of technology such as supply chain management software, businesses can now have real-time visibility and insights into their entire supply chain.

Technology has also enhanced communication and collaboration within the supply chain. With the help of digital platforms and tools, suppliers, manufacturers, logistics providers, and customers can easily communicate and share information, leading to improved coordination and efficiency.

Moreover, technologies such as automation, artificial intelligence (AI), and machine learning have also helped streamline various processes within the supply chain. For instance, automated warehouses can significantly reduce the time it takes to pick and pack orders, improving overall speed and accuracy in fulfillment. AI-powered demand forecasting can help businesses make more accurate predictions and optimize inventory levels accordingly.

In conclusion, technology has revolutionized supply chain management and will continue to play a crucial role in driving efficiency, visibility, and sustainability in the future. By embracing technological advancements and continuously innovating, businesses can ensure their supply chains are equipped to handle any challenges that may arise and support sustainable growth for years to come.

Managing the Bottlenecks in a Supply Chain

Thus, we have learned about the possible ways to recognize the bottlenecks in a supply chain. Along similar lines, let us guide you about getting rid of them by being operationally sound. Being ready to tackle the problems once they affect the supply chain is not an ideal approach.

- Be proactive rather than waiting for a problem to show up to do something about it.

- Bottlenecks should be predicted when the process is planned to avoid destructive consequences whenever a problem arises.

- Developing layered systems to deal with different functionalities and implementing IT systems to use available information and data.

- Proper planning about the availability of cash in the supply chain if a disruption occurs. Not only planning but a certain amount of cash should likewise be dedicated for emergencies.

- Prioritize visibility along the supply chain, depending on the order of most noticeable financial impact.

- Adopt artificial intelligence and different advanced technologies to get to the bottom of analytic value from gathered data and distinguish the bottlenecks along the supply chain.

- Do not have a single-source supplier; having multiple domestic and international suppliers will assist you with becoming operationally sound.

- Take advantage of bulk order discounts that are usually set on raw materials.

- In addition, you should work with an import service provider to help you take your products to their destination.

- Take advantage of automated tasks, driving a reliable and efficient line.

In conclusion

The above are the ways to identify the bottlenecks in supply chain management, which is the most crucial step to be proactive about predictable issues. The ways to identify are followed by ways to tackle and manage the recognized bottlenecks through process mapping, which eventually helps you become operationally sound. Remember, a business might experience labor or technology shortage, so operationally sound means making fewer people and technologies more productive. For more information book a no obligation consultation today.