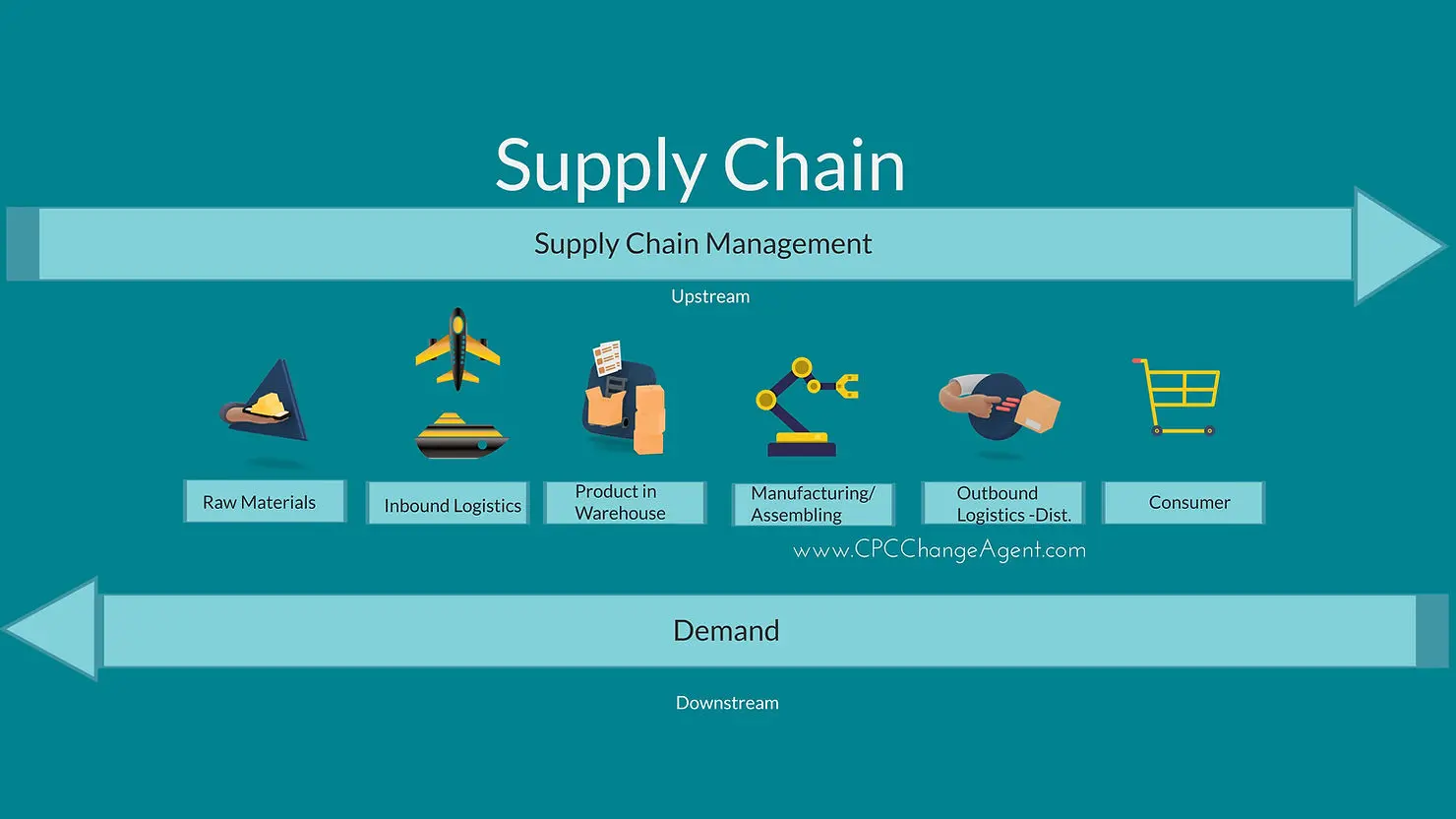

Let’s begin with defining a supply chain. A supply chain is a workflow between a company and its suppliers to produce and distribute a specific product to the final buyer. It’s a long definition, but we’re here to walk you through everything you should know.

A supply chain is a vital aspect of any business, as it allows for the efficient production and distribution of goods. In today’s global market, supply chains have become more complex and interconnected than ever before. This has led to increased competition and a greater need for companies to optimize their supply chains.

To understand the importance of supply chains, we must first recognize the key elements that make up a supply chain. These include suppliers, manufacturers, distributors, retailers, and customers. Each element plays a crucial role in the overall functioning of the supply chain.

Suppliers are responsible for providing raw materials or components to manufacturers. Manufacturers then use these materials to produce finished goods which are then distributed to retailers. Retailers then sell these products to customers.

Next, who are your suppliers? Suppliers are both internal like finance, IT, and operations, and external like manufacturers, and inbound and outbound logistics (how the supplies, goods, or services get to you and your customers). There are so many more pieces to the supply chain, but these are only a few. There are many moving parts in a supply chain, which is why it’s important to have effective management and coordination among all elements.

One key factor in successful supply chain management is communication. Effective communication between suppliers, manufacturers, distributors, and retailers can ensure the smooth flow of goods from start to finish. This includes not only updates on production and delivery schedules but also sharing information on market demand and potential disruptions.

Another crucial aspect of supply chain management is risk mitigation. As supply chains become more integrated, they also become more vulnerable to risks such as natural disasters, political instability, or unexpected events like the current COVID-19 pandemic. Companies must have contingency plans in place to handle these types of risks and minimize their impact on the supply chain.

Optimizing supply chains also involves utilizing technology and data. With the advancement of technology, companies now have access to real-time data that can help them make more informed decisions. This includes forecasting demand, tracking inventory levels, and identifying areas for improvement in the supply chain.

Supply chains are a complex but essential part of any business. Proper management and coordination among all elements, effective communication, risk mitigation strategies, and utilizing technology will help businesses stay competitive in today’s global market. And as supply chains continue to evolve, companies must be willing to adapt and innovate to stay ahead of the game. So keep learning and exploring new ways to enhance your supply chain – the possibilities are endless!

Key Elements of a Supply Chain

In this article, we will talk about how important it is to look at the entire picture when you want to improve your supply chain workflow, and how process and technology stack mapping is a critical component in warehouse, manufacturing, and logistics. But first, let’s dive into the key elements of a supply chain.

Supplier Management:

When it comes to managing suppliers, communication is key. It’s important to maintain open lines of communication between all parties involved in the supply chain – from suppliers to manufacturers to retailers. This not only helps with transparency but also allows for proper planning and coordination.

Manufacturing:

The manufacturing stage is where raw materials or components are transformed into finished goods. This process requires efficient planning and coordination to ensure the smooth flow of production.

Distribution:

After goods are manufactured, they must be delivered to retailers for sale. The distribution stage involves logistics and transportation to get products from the manufacturer to retail locations.

Retail:

Retailers play a crucial role in the supply chain as they are the final link between the product and the customer. They must manage inventory levels, sales data, and third-party logistics to ensure products are available for purchase.

Customer:

Last but certainly not least, customers are at the center of the supply chain. Their demand for products drives the entire process and it’s important for businesses to have a clear understanding of their needs in order to effectively manage the supply chain.

By understanding each element of the supply chain and its role in the overall process, businesses can better identify areas for improvement and implement strategies to optimize their supply chain. This includes improving communication, utilizing technology and data, and effectively managing risks.

As we continue to see advancements in technology and changes in the global market, it’s crucial for companies to regularly review and adapt their supply chain strategies in order to stay competitive. By staying informed and taking a holistic approach to supply chain management, businesses can ensure the efficient production and distribution of goods, ultimately leading to increased customer satisfaction and business success. So keep exploring and innovating – the possibilities for improvement are endless! Overall, it’s clear that a well-managed supply chain is essential for the success of any business, and understanding its key elements is the first step towards achieving this goal. So remember to always analyze and optimize your supply chain – it’s a continuous process that can help your business thrive in today’s ever-changing market. Now let’s explore some ways to further enhance your supply chain efficiency through technology and data utilization.

Utilizing Technology and Data in Supply Chain Management

In today’s constantly evolving business landscape, companies must stay ahead of the game by utilizing advanced technology and data to optimize their supply chain processes. Let’s take a closer look at some key ways to incorporate technology and data into supply chain management.

- Forecasting Demand:

By utilizing data such as sales history, market trends, and customer feedback, companies can make more accurate predictions and forecasts for demand. This helps in planning production schedules, managing inventory levels, and ensuring timely delivery of products.

- Real-time Tracking:

With the help of technology such as GPS and RFID tracking systems, companies can monitor the movement of goods in real time. This provides better visibility into the supply chain and allows for quick identification and resolution of any issues that may arise.

- Inventory Management:

Technology allows for real-time tracking and management of inventory levels, reducing the risk of overstocking or stockouts. It also streamlines processes such as order fulfillment and replenishment.

- Supply Chain Analytics:

Data analytics can provide valuable insights into supply chain performance, identifying areas for improvement and optimization. Companies can use this data to make informed decisions and continuously improve their supply chain processes.

Communication and Collaboration:

Technology also plays a crucial role in facilitating communication and collaboration among all parties involved in the supply chain. With tools such as cloud-based platforms, suppliers, manufacturers, retailers, and customers can easily share information and coordinate efforts.

By incorporating technology into the supply chain, companies can achieve greater efficiency, reduce costs, and improve overall performance. It also allows for better risk management by providing real-time data and visibility into potential disruptions.

A successful supply chain requires a holistic approach that incorporates effective communication, efficient processes, and advanced technology. By continuously evaluating and adapting strategies with the help of technology and data utilization, companies can stay competitive in today’s fast-paced business world. So don’t hesitate to embrace innovation and utilize technology in your supply chain management – it may just be the key to success! So keep exploring and innovating – the possibilities for improvement are endless!

One of our distinctions at CPC Change Agent from other operations organizations is we cover end-to-end, and that is deliberate. We understand the importance of connecting all the dots in your business operations and having a connected supply chain workflow. This allows for better communication and collaboration, process optimization, and ultimately leads to a more efficient supply chain. By partnering with CPC Change Agent, businesses can gain the advantage of our expertise in end-to-end supply chain management, with a focus on utilizing technology and data for continuous improvement. So let’s continue working towards a seamless and optimized supply chain – together! As we conclude our discussion on the key elements and ways to enhance supply chain management, it’s important to remember that the success of a business depends heavily on how well its supply chain is managed. And with the ever-changing market and technological advancements, continuously analyzing and improving your supply chain is crucial for staying ahead of the game. So keep exploring, adapting, and innovating – because in the world of supply chain management, the possibilities for improvement are endless. So let’s continue working towards a seamless and optimized supply chain – together! Remember, your supply chain is not just a cost center, but rather a valuable asset that can drive business success. So invest in it wisely and stay ahead of the competition. The future of your business depends on it.

Smarter, Faster, Cheaper…Better?

When we talk about supply chains, you may hear terms like upstream and downstream. That is referring to the supply chain flow from your raw materials to your customer and how that will change with supply and demand. This is where technology and data can play a crucial role in predicting and managing these changes effectively. By utilizing real-time tracking, demand forecasting, and supply chain analytics, companies can make faster and smarter decisions that lead to cost savings, improved efficiency, and increased customer satisfaction. This ultimately results in a stronger and more competitive supply chain.

In addition, advancements in technology have also led to the rise of “smart” supply chains, where machines and systems are connected and can communicate with each other in real time. This allows for automated processes, proactive issue resolution, and improved overall performance. With the help of data analytics, these smart systems can constantly learn and improve, creating a never-ending cycle of efficiency and cost savings.

Technology and data utilization are crucial elements for success in supply chain management. By embracing these advancements and continuously evaluating and improving strategies, companies can stay ahead of the competition in today’s rapidly evolving business landscape. So don’t wait – start incorporating technology and data into your supply chain processes now to drive

There are a lot of supply chain variations, depending on your business and industry. Creating a connected supply chain and understanding the interdependencies helps your business run most efficiently and effectively. There are many preventative measures we can address in supply chain issues to ensure you are set up from a continuity perspective as well as a plan of action if an accidental disaster occurs. Staying on top of your supply chain, looking at costs to produce, identifying the cost of inbound and outbound logistics, setting up your warehouse, and managing personnel is a constant effort. The CPC Change Agent experts are equipped to assist your business in making the most educated decisions that will positively impact your bottom line. With our expertise and use of technology and data, we can help you optimize your supply chain processes for maximum performance – ultimately leading to a smarter, faster, cheaper, and better supply chain!

Stacked Technology

I can’t stress this point enough; looking at the entire picture of your business is the only way to ensure all the different pieces make sense when they come together. Integrating your technology, using design thinking for your user experience, and allowing shared data across platforms and lines of business will allow your team to make accurate operational decisions in real time as well as be able to adjust the strategy to meet the company’s goals. Without the right supporting technology, this can make things incredibly difficult for your team.

Domino effect

Once you adjust one thing within your supply chain, everything else can be affected. We discussed the importance of having technology that’s not only appropriate for your business but gives real-time data that’s visible to leadership. Now we’re going to explain what that means, and the domino effect it has. By having visibility into your entire supply chain, you can see how changes in one area affect another. For example, if there is a delay in production, this will impact inventory levels and potentially lead to stockouts or excess inventory. With real-time data, you can quickly adjust orders or production schedules to mitigate these issues before they have a larger impact on the supply chain flow.

When clients tell us there are gaps in their supply chain, we must look at everything in depth, especially technology. Decision-making in logistics can be cost-driven in many cases. Business leaders are always looking to cut costs at the moment because tomorrow’s prices can be driven up by circumstances out of our control. It becomes the constant task of running simulations to get the best possible outcome. For example, if a leader decides to change the delivery date of this purchase order, they need to figure out is the impacts it can have on their ability to meet customer demand, or if they order fewer products, will that drive the cost of the product per unit and import logistics up but the demand has dropped? Whatever you decide, it will affect other aspects of your supply chain – good and bad.

Overall, investing in technology and data for your supply chain can seem like a daunting task. However, the benefits are well worth it – not only in terms of cost savings and efficiency but also in staying ahead of the competition. By constantly evaluating and optimizing your supply chain processes, you can create a smarter, faster, cheaper, and better supply chain that will drive business success. Let CPC Change Agent help you navigate the complex world of supply chain technology and data utilization – contact us today to learn more!

Continued Learning

As technology and data continue to advance, it is important for supply chain professionals to continuously educate themselves on new trends and tools to stay competitive in the industry. This can include attending conferences, networking with other professionals, and staying up-to-date on industry publications and news. By actively seeking out opportunities to learn and improve, supply chain managers can stay ahead of the curve and make informed decisions for their businesses.

Moreover, investing in training and development programs for employees is crucial for successfully implementing technology and data-driven strategies. This not only ensures that team members are equipped with the necessary skills and knowledge but also fosters a culture of continuous improvement within the organization.

In conclusion, incorporating technology and data into supply chain management is not a one-time task, but rather an ongoing process that requires constant learning and improvement. By embracing this mindset and utilizing the right tools and strategies, businesses can create a never-ending cycle of efficiency and cost savings – ultimately leading to long-term success and growth.

Maps, Maps, Maps

I tell leaders all the time if you have tried to fix an issue by throwing money, technology, and personnel at it, but you still have the problem, map it! If they’re drawn right, they provide you with insight into your entire business. The distinction between us and others is our maps. We spend an enormous amount of time finding the root causes of your business issues. We analyze your entire network to identify bottlenecks, fragility, and opportunities for optimization. That applies to your technology, processes, people, and customer experience. When we talk through our findings, you can feel assured that the issues are identified and will be resolved.

Lead time

We know that warehousing wherever you are in this equation is all about the lead time, the time between the initiation and completion of a production process. The faster you can turn that around, the more money you will make, the more customers you can sell to, and the faster you turn over the product. Employee effectiveness begins with setting up a warehouse properly and adjusting the product placement by SKU velocity. We must also consider the wear and tear it has on our people. In some cases, our warehouse upgrades have included reorganizing the setup and installing RaaS or Robots-as-a-Service. Yes, they are cool. Yes, your business must be set up properly, but you also must have the right technology for it. Work with professionals to configure all your processes and systems, but that’s for another article.

In closing, if you are in the manufacturing and logistics space and you know you have operational gaps or are feeling frustrated with the way the business workflows are hindering growth, we’re here to help. Book a consultation with one of our experts today and learn more about how we can help your business thrive in the ever-evolving world of supply chain management. We offer a range of services from supply chain optimization to data analytics and technology implementation, all tailored to your specific needs.